You’ve been mowing your lawn for a while when it just stops working. I’ll go through some items that can cause this to happen so you can try to get your mower up and running again.

A push mower quits when hot when the air filter is plugged; the engine oil level is too high or too low; the engine oil is wrong; the carburetor is dirty; the fuel cap is bad; the fuel is old; the spark plug is bad; the ignition coil is faulty; the cooling fins are plugged, or the mower deck is plugged.

Follow the safety procedures listed in your operator’s manual. This includes waiting for the engine to cool and all moving parts to stop moving. Remove the spark plug wire before performing repairs.

This post may include affiliate links. Purchases made through these links may provide a commission for us, at no extra cost to you. As an Amazon Associate, we earn from qualifying purchases.

Follow all safety instructions provided in your equipment operator’s manual before diagnosing, repairing, or operating. Consult a professional if you don’t have the skills, or knowledge or are not in the condition to perform the repair safely.

Reasons a Push Mower Quits When Hot

Plugged Air Filter

Check the air filter. If it’s not changed regularly, it can become so plugged with dirt and debris that the mower stops running. This is because the engine is starved of the air it requires.

The air filter is a preventative maintenance item that is necessary to protect the engine from dirt contamination. It must be kept clean.

Not only can the push mower quit running, but it can cause the mower to overheat potentially damaging the engine.

I recommend starting each mowing season with a new air filter. You should check it regularly and clean it several times a year.

If you use your push mower in very dusty conditions, you will have to clean and replace it more frequently.

Checking and cleaning the air filter filter is a simple task. Taking a few minutes to check the air filter can save you from more severe problems.

SOLUTION: Clean the air filter by removing it from the air filter housing. Be careful and don’t knock dirt into the air intake.

Wipe out any dirt that remains in the housing with a dry clean cloth. Follow these instructions to clean your mower filter type:

Clean a paper lawn mower air filter:

- Tap your paper filter element against a solid surface to loosen and remove dirt. Get as much dirt out as possible. Do not use compressed air to clean the filter as this will damage it.

- Hold your filter up to a light source to check for light shining through the paper.

- Reuse a filter when you can see light through the paper. Replace with a new air filter when you cannot see light, the filter is wet, or the filter is damaged.

- Install the filter into the air filter housing and reattach the housing cover.

Clean a foam lawn mower air filter:

- NOTE: These are instructions for a primary foam filter. These are NOT for a foam pre-filter that may be used in conjunction with the primary filter.

- Check the condition of the foam air filter. Replace it with a new one if you notice it is dry, brittle, has a tear, or has developed brown spots.

- If your filter is in good condition, proceed with washing it with mild dish soap and water. Remove the dirt and oil from the filter.

- Rinse the filter until it rinses clear and all soap has been removed.

- Lay flat to air dry. Place it in the sun to help it dry faster.

- Use filter oil to coat your filter. Squeeze out any excess oil from the filter. You don’t want the filter to be dripping oil. (Never apply oil to a foam pre-filter).

- Reinstall the filter into the filter housing and reattach the cover.

Old Fuel

Old fuel is often the reason a mower quits after it’s been running a while. This is because old fuel can leave behind varnish and sticky deposits that can cause component failures and fuel restrictions.

When the engine isn’t able to get sufficient fuel, it will begin to run sluggishly and possibly die. To reduce fuel issues developing in a push mower, always run fresh gasoline with low ethanol content.

Mowers require unleaded gasoline with less than 10% ethanol content. While ethanol-free fuel is best, never use gas that contains for than 10% ethanol.

Determine the type of engine you use to determine the fuel required.

- 4-cycle push mower engines require a straight gas.

- 2-cycle push mower engines require a gas and 2-cycle engine oil mixture.

Read more about choosing the right gas in This is the Gas to Use in a Push Mower (Don’t Get It Wrong).

Repair: Drain the fuel tank into an approved fuel storage container using a siphon pump. You may also be able to remove the fuel line from the carburetor and allow it to drain in a container.

Add fresh fuel to a fuel can and add a fuel additive like Sea Foam Motor Treatment to the fuel to clean the fuel system, reduce moisture, and stabilize the fuel. This is why I choose to use Sea Foam in every tank of fuel.

Dirty Carburetor

The carburetor regulates the amount of fuel that mixes with air to form combustion in the cylinder. Varnish left behind by old fuel can clog the passageways and cause internal parts to stick so they no longer function.

This will prevent fuel from getting to the engine and the mower will quit running.

Before tearing the carburetor apart to clean it, perform a couple of steps to confirm whether the running problem is due to a dirty or bad carburetor. First, make sure you are getting fuel to the carburetor.

Second, remove the air filter and spray carburetor cleaner into the air intake. Start your mower. If it runs for a bit and then shuts down, you will need to disassemble your carburetor and clean it.

SOLUTION: If you are a little mechanical and don’t mind working with a lot of small parts, you should be able to handle cleaning your carburetor. Follow the instructions in this article to clean the carburetor on your lawn mower.

You can also have your local lawn mower repair shop clean the carburetor if you choose to not tackle the task yourself.

Wrong Type of Engine Oil

The best kind of oil for your push mower is air-cooled engine oil that contains a high concentration of zinc. Zinc is used as a cooling agent.

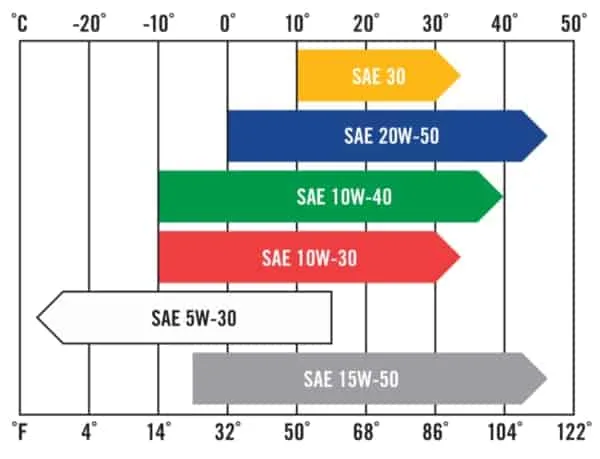

The cooling procedure differs from cars. Cars use liquid to cool their engines and small engines use air for cooling. Most lawn mower small engine manufacturers recommend using SAE30 or 10W-30 engine oil.

While this is the recommendation and good for most areas, you may have to change to using a different viscosity, like 20W-50 when operating in higher ambient temperatures.

Use this chart provided by Kawasaki Motors along with your operator’s manual to select the correct engine oil for your lawn mower.

Running the wrong engine oil can result in overheating your engine causing it to shut down.

SOLUTION: When you find the engine oil is not correct, drain the oil and fill it with the appropriate fresh air-cooled engine oil.

Low Engine Oil Level

You need to check the engine oil level before you use your mower. Running a mower that’s low on oil can cause the engine to overheat and shut down.

Oil is required to keep the internal parts of the engine lubricated. When there isn’t enough oil in the crankcase, the moving parts create friction and heat.

The heat can intensify and become so hot that oil begins to thicken and parts begin to melt. This can result in severe engine damage. You may end up having to replace the mower with a new one.

SOLUTION: You can attempt to correct the engine oil level and try to start your mower to see if it runs. Most likely, once your mower shuts down due to a low engine oil issue, you have already caused extensive engine damage.

Have an experienced small engine mechanic perform tests on your engine to determine the extent of the damage. Running your lawn mower with a low oil level can result in needing an engine replacement.

It is usually most cost-effective to purchase a new mower instead of replacing the engine.

Too Much Engine Oil

Most people understand it is important to not run the engine low on oil. However, they don’t always understand too much oil in the crankcase can also cause engine problems.

Overfilling the crankcase with engine oil causes increased pressure in the crankcase.

It causes the crankshaft and rod to not move freely because they have to push through excess oil. This can put the internal engine parts under load causing the engine to get hot and quit.

In addition to this, running too much oil in the mower can push oil into the cylinder through the valve train causing a thick cloud of smoke when the oil burns off.

This smoke can plug the filter and start the engine of air making it shut down.

SOLUTION: Remove excess oil to bring it to the recommended oil level as indicated on the oil dipstick. Before you start, disconnect the spark plug wire(s) so your engine doesn’t start.

You can drain a little oil through the drain plug or oil fill port. I like to remove a little oil using a turkey baster because it’s convenient and not too messy of a process.

Once you have drained a little oil, check the oil level using the dipstick. Drain or add engine oil as needed to correct your engine oil level.

Check your air filter to make sure it isn’t plugged from the smoke if your mower started to smoke before it quit. Reattach the spark plug wire(s).

If you still experience problems after correcting your engine oil level, have an engine mechanic check it out.

Damaged or Clogged Engine Cooling Fins

The cooling fins help dissipate heat to keep the engine block and cylinder cool. The cooling fins should be cleaned annually and kept free of debris that will prevent it from circulating air around the engine.

When the engine isn’t kept cool, it can overheat and quit.

SOLUTION: Remove debris around your cooling fins and replace any broken fins. Remove any dirt collecting around your engine shroud.

Bad Spark Plug

A dirty spark plug that has carbon buildup, broken porcelain, or burnt electrode can fail to create spark. This will cause a push mower to quit. It may have provided enough spark to start your mower, but now it can’t keep it running.

SOLUTION: Check the plug for signs of buildup on the tip and clean it if necessary. If you find the tip to be extremely dark or find damage, you must replace your spark plug.

Check your spark plug wires and make sure they are securely attached as this can also cause your mower to quit running.

Bad Ignition Coil

When the coil gets hot, the windings on the coil can separate and short out. The coil provides voltage to the spark plug. The mower will quit running.

SOLUTION: Use an ohmmeter to test your ignition coil to confirm there isn’t a break in the continuity. Replace the coil when you find it is bad.

Clogged Fuel Cap

The fuel cap is designed to allow air to pass through it. This is to keep the equalize the air pressure inside the fuel tank to that outside of the tank.

When the cap fails to vent, the fuel tank forms a vacuum that keeps the carburetor from getting gas. This can cause a mower to stop running after you have been mowing with it.

SOLUTION: Check the condition of your gas cap by allowing your mower to run with the gas cap tightened and with the gas cap loosened to allow air into the tank.

If the push mower eventually shuts off when the cap is tightened, but runs fine when it is loosened, you most likely have a problem with your fuel cap.

Replace the fuel cap with a new one.

Plugged Mower Deck & Dull Blades

A mower deck that is packed full of grass and dirt can put extra strain on the engine causing it to overheat and shut down.

The engine must work harder to turn the mower blade(s) through the plugged deck. Running a mower with dull mower blades further magnifies the problem.

SOLUTION: Scrape your deck periodically and sharpen the mower blades. Not only does it provide a better cut, but it also prevents an overload on your engine.

Prevent the amount of grass buildup by not mowing in wet conditions.